Testing & Certification

- Compliant to Australian, New Zealand & International Standards

- TÜV Rheinland approval

- Successfully tested for vibration endurance

- Avoids health and safety implications of alternative construction methods

Quality Management System

Interclamp Pty Ltd operates a formal Quality Management System which was certified to ISO9001:2008

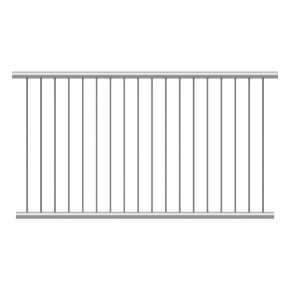

AS 1657:2018 - Fixed Platforms, Walkways, Stairways & Ladders: Design, Construction & Installation

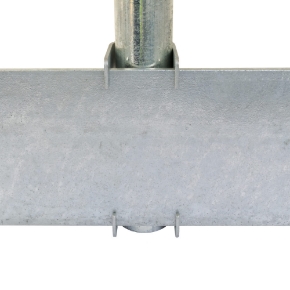

Typical Interclamp installations of our Traditional Range, DDA Assist and Pedestrian Barriers have been successfully proof load tested in both C42 and D48 sizes in compliance with the procedures specified in AS 1657:2018, by an independent NATA and ISO/IEC 17025 accredited test house in Melbourne.

AS 1428.1:2009 Design for Access & Mobility Part 1: General Requirements for Access – New Building Work

Interclamp DDA Assist fittings may be used to build handrails that conform to AS 1428.1:2009. As this standard is for finished structures, it is important that the correct Interclamp fittings and other materials (most notably tube, fixings and existing structure or substrate to which the Interclamp structure is attached) are chosen for each application and that the complete structures are both suitably designed and installed to meet the requirements of the standard.

AS 1170:2002 Structural Design Actions

The Interclamp system may be used to construct barriers, parapets, balustrades and railings conforming with the requirements of AS 1170, subject to correct choice of materials, design of the structure and dependent on the type of occupancy defined by Table 3.3 of the standard.

AS 5100.2:2017 Bridge Design Part 2: Design Loads

With careful design and selection of materials, pedestrian and cyclist path barriers incorporating Interclamps may be built to meet this demanding standard.

Australian Market only: Interclamp® Compliance Statement

A Compliance Statement, which makes reference to the most relevant Australian Standards is available on request. It includes details of Inspection, Testing & Servicing requirements, in order to satisfy the needs of the standards.

TÜV Rheinland – Product Safety Type Approval

The core range of Interclamps is subject to periodic rigorous testing and continuous product safety type approval by TÜV Rheinland, the leading independent test house across the globe.

BS EN 60068-2-6 Environmental Testing (Vibration)

In accordance with BS EN 60068-2-6, a British UKAS-Accredited test house conducted seven resonance (vibration) endurance tests, each of six hours duration, plus an additional six hour swept endurance test between the frequencies of 74Hz and 87Hz on one axis. After each resonance endurance dwell, the setscrews were visually checked for any movement. Throughout the whole test programme, there was no evidence of any loosening of the setscrews. Further technical information relating to the test is available on request.

Beam Tests

Beam tests for uniformly-distributed loads have been successfully carried out by an independent British load test facility. Further details are available on request.